The sketch and locating dimensions are retained.

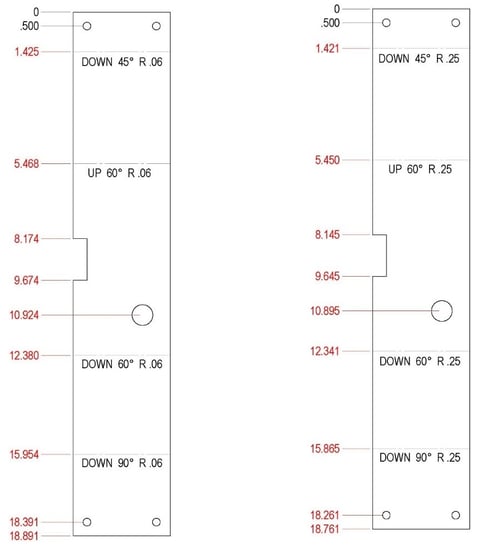

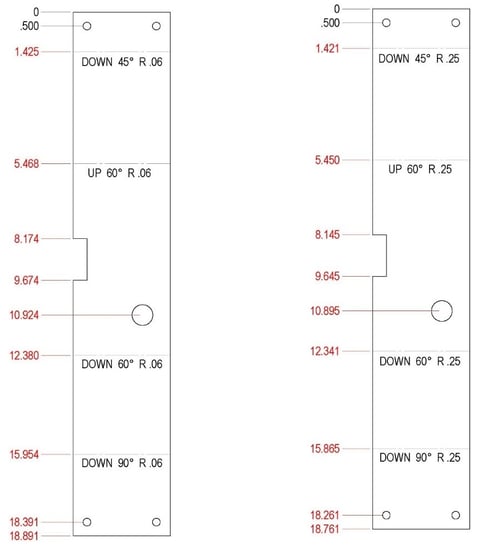

Dimensioning sheet metal flat pattern.

Flat patterns of all bodies appear at the end of the featuremanager design tree.

Oml outside mold line the intersection of two outside surfaces of a part extended past the bend.

Multibody sheet metal parts.

Here are the steps to be followed to calculate sheet metal flat length.

This can be a physical drawing or template or a computer model.

The flat pattern drawing doesn t always list these factors.

I think this is the better way because you can acquire your cutting length without a flat pattern by adding the inside lengths fold allowance.

Dimensions given on a flat pattern are affected by several bending factors like k factor and bend radius during the 3d modeling stage.

And also find you fold centers more easily.

Generally capabilities of of 0 9mm 20mm in thickness are able to be manufactured from sheet 3mm or plate 3mm but this tolerance depends mainly on the part.

Bend allowance ba π 180 r k t a.

Enter flange length internal radius and thickness values.

Sheet metal flat length can be calculated in the following three simple steps.

Calculate the value bend allowance for required sheet metal bend by using below formula.

The flat pattern drawing doesn t always list these factors.

Keep default values in calculator as zero.

When you expand the representation of a body in the cut list the body s flat pattern appears at the end of its feature list.

Value of bend deduction and flat pattern are shown in result section.

If the value of sheet metal k factor and bending flange length is known.

When producing drawings of sheet metal components i dimension from inside the flange walls.

Flat pattern terminology iml oml c l radius flat pattern the outline definition of the part in it s flat state before forming.

Enter k factor values.

Lets go ahead and include all the fastener locations.